How Long Does a Forklift Battery Last? Your Guide to Smarter Power Choices

Are you wondering how long a forklift battery lasts? Choosing the right forklift battery can transform your warehouse’s efficiency, cut downtime, and save costs. As a warehouse manager or operator, I know you need reliable power to keep operations humming. With years of industry experience, I’m sharing a no-nonsense guide to forklift battery lifespan, packed with practical insights to help you make informed decisions. From lead-acid to lithium-ion batteries, you’ll discover what impacts their longevity and how to maximize performance. Let’s power up and dive in!

Understanding Forklift Battery Lifespan

Knowing how long a forklift battery lasts is essential for managing warehouse operations efficiently. The lifespan of a forklift battery varies depending on its type and how it’s used and maintained. Typically, forklift batteries last anywhere from 3 to 6 years, but this can change based on several factors.

Average Lifespan by Battery Type

- Lead-Acid Batteries: These are the traditional choice for electric forklifts and usually last about 4 to 6 years with proper care.

- Lithium-Ion Batteries: Known for their longer cycle life, lithium-ion batteries can last between 5 to 7 years or more, making them a cost-effective option over time.

Factors Affecting Battery Lifespan

Several key factors influence how long your forklift battery will perform well:

- Charging Practices: Overcharging or undercharging can significantly reduce battery life.

- Maintenance: Regular cleaning, watering (for lead-acid), and inspections help maintain battery health.

- Usage Patterns: Frequent deep discharges and heavy workloads can shorten lifespan.

- Environmental Conditions: Extreme temperatures and poor ventilation affect battery efficiency.

- Battery Quality: Higher-quality batteries and better manufacturing lead to longer-lasting performance.

Understanding these elements helps you make smart decisions for battery use, maintenance, and when to plan for replacement, ensuring your operations run smoothly and cost-effectively.

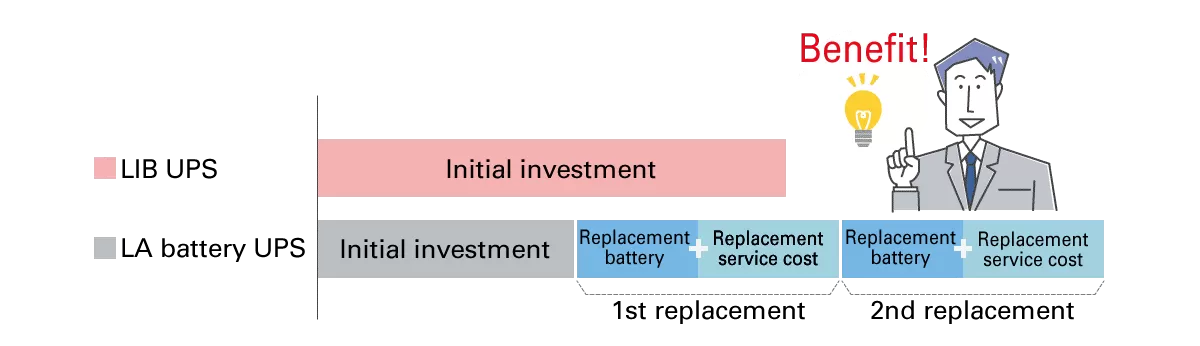

Lead-Acid vs Lithium-Ion A Lifespan Comparison

When comparing forklift battery lifespan, lead-acid and lithium-ion batteries are the two main options you’ll encounter. Each has its strengths depending on your operation’s needs.

Lead-Acid Batteries

Lead-acid batteries have been the industry standard for years. Typically, they last about 1,200 to 1,800 battery cycles, which translates to 3 to 5 years with proper lead-acid battery maintenance. These batteries require regular watering, cleaning, and scheduled equalizing charges to keep their performance steady. While they’re generally less expensive upfront, long charging times and downtime for maintenance can affect warehouse battery efficiency. Plus, they’re bulkier and heavier compared to lithium-ion.

Lithium-Ion Batteries LI-ESS Focus

Lithium-ion forklift batteries, like those from LI-ESS, are gaining ground fast. They last roughly 2,000 to 3,000 battery cycles, which can stretch the battery life to 6-8 years, sometimes longer. Lithium-ion batteries offer faster charging, opportunity charging benefits, and reduced maintenance since you don’t have to worry about watering or acid spills. The LI-ESS line, made with quality and reliability in mind, offers top-tier performance that fits well with modern electric forklift operations in the US market.

Which Is Right for Your Operation

If your warehouse runs multiple shifts and needs fast charging with minimal downtime, lithium-ion, especially LI-ESS batteries, can save you time and money over the long haul. But if your operation has a tighter budget and can manage regular maintenance, lead-acid batteries are still a reliable choice. Consider your use frequency, budget, and maintenance capabilities when deciding which forklift battery type fits your operation best.

Maximizing Forklift Battery Life Practical Tips

Getting the most out of your forklift battery means following a few simple but important steps. Whether you’re using a lead-acid battery or a lithium-ion forklift battery, proper care extends electric forklift battery life and saves you money in the long run.

Proper Charging Practices

- Charge at the right time: Avoid fully draining the battery before charging. Opportunity charging during breaks keeps the battery healthier.

- Use the correct charger: Match your battery’s voltage and type. For example, lead-acid needs a different charger than lithium-ion.

- Avoid overcharging: Overcharging can cause battery damage and reduce battery cycle life. Use chargers with automatic shut-off features.

Regular Maintenance

- Inspect regularly: Check for corrosion, loose cables, and damaged connectors.

- Keep it clean: Dirt and debris can affect battery contacts and performance.

- Water lead-acid batteries: Maintain proper water levels and use distilled water to avoid damage. Lithium-ion batteries require less maintenance but still need periodic checks.

Environmental Considerations

- Store properly: Keep batteries in a cool, dry place away from extreme temperatures.

- Avoid harsh conditions: Excessive heat or cold can shorten forklift battery lifespan.

- Ventilation is key: Especially for lead-acid batteries, ensure good ventilation when charging to avoid buildup of gases.

Monitoring Battery Health

- Use monitoring tools: Many forklift batteries come with built-in indicators or smart monitoring systems.

- Track charge cycles: Knowing your battery’s cycle count helps plan for replacement and avoid unexpected downtime.

- Schedule professional inspections: If performance drops or you notice issues, get a battery professional to inspect it.

Following these tips keeps your forklift battery in top shape, boosts warehouse battery efficiency, and helps your operation run smoothly.

Why Choose LI-ESS Lithium-Ion Forklift Batteries

If you’re thinking about upgrading your forklift battery, LI-ESS lithium-ion batteries are a solid choice. They deliver longer forklift battery lifespan and better performance compared to traditional lead-acid batteries. Here’s why LI-ESS stands out for warehouse operations across the US:

-

Longer Battery Cycle Life

LI-ESS lithium-ion batteries can handle more charge cycles before needing replacement. This means fewer battery swaps and lower forklift battery replacement costs over time.

-

Fast and Opportunity Charging

You can quickly recharge these batteries during short breaks, keeping your electric forklift battery life active throughout long shifts without downtime. This leads to better warehouse battery efficiency.

-

Low Maintenance

Unlike lead-acid batteries, LI-ESS lithium-ion batteries require minimal upkeep. No need for watering or equalizing charges, which simplifies forklift battery maintenance and saves you time.

-

Consistent Power Delivery

LI-ESS batteries maintain steady voltage throughout their discharge, ensuring your forklift runs smoothly without performance drops or slowdowns.

-

Safer and Environmentally Friendly

Built with quality and safety in mind, LI-ESS packs reduce the risk of fires or leaks common in older battery types. Plus, they’re more eco-friendly, which aligns well with increasing industry sustainability standards.

-

Cost Savings Over Time

Although the upfront price might be higher than lead-acid options, the longer battery lifespan, reduced maintenance, and improved efficiency mean lower total cost of ownership.

Choosing LI-ESS lithium-ion forklift batteries means investing in reliable power that fits well with the fast pace and demands of US warehouses and industrial sites. Their proven quality and focus on performance make them a smart pick to keep your operation running smoothly.

FAQs

How long does a forklift battery last?

The average forklift battery lasts between 4 to 6 years, but this depends on battery type, usage, and maintenance.

What affects forklift battery lifespan the most?

Factors like charging habits, maintenance, operating environment, and cycle frequency all impact battery life.

Which lasts longer lead-acid or lithium-ion forklift batteries?

Lithium-ion batteries typically last longer, around 6 to 8 years, while lead-acid batteries average 4 to 6 years with proper care.

How often should I charge my forklift battery?

Charge batteries regularly and avoid deep discharges. For lead-acid, a full charge after each use is best. Lithium-ion supports opportunity charging, so shorter, more frequent charges work well.

What’s the best way to maintain my forklift battery?

Keep terminals clean and tight

Regularly check electrolyte levels in lead-acid batteries

Use proper chargers for your battery type

Store batteries in a cool, dry place

Can I use lithium-ion batteries in my existing forklift?

Some forklifts can be retrofitted for lithium-ion, but check compatibility with your supplier or manufacturer.

Is opportunity charging beneficial?

Yes, especially for lithium-ion batteries. It helps maintain charge without hurting battery life, boosting warehouse efficiency.

When should I consider forklift battery replacement?

If you notice a sharp drop in run time, longer charging time, or physical damage, it might be time to replace the battery. Regular monitoring helps catch these signs early.