How Long Does a Forklift Battery Last? Your Guide to Smarter Power Choices

Are you wondering how long a forklift battery lasts? Choosing the right forklift battery can transform your warehouse’s efficiency, cut downtime, and save costs. As a warehouse manager or operator, I know you need reliable power to keep operations humming. With years of industry experience, I’m sharing a no-nonsense guide to forklift battery lifespan, packed with practical insights to help you make informed decisions. From lead-acid to lithium-ion batteries, you’ll discover what impacts their longevity and how to maximize performance. Let’s power up and dive in!

Understanding Forklift Battery Lifespan

Knowing how long a forklift battery lasts is essential for managing warehouse operations efficiently. The lifespan of a forklift battery varies depending on its type and how it’s used and maintained. Typically, forklift batteries last anywhere from 3 to 6 years, but this can change based on several factors.

Average Lifespan by Battery Type

- Lead-Acid Batteries: These are the traditional choice for electric forklifts and usually last about 4 to 6 years with proper care.

- Lithium-Ion Batteries: Known for their longer cycle life, lithium-ion batteries can last between 5 to 7 years or more, making them a cost-effective option over time.

Factors Affecting Battery Lifespan

Several key factors influence how long your forklift battery will perform well:

- Charging Practices: Overcharging or undercharging can significantly reduce battery life.

- Maintenance: Regular cleaning, watering (for lead-acid), and inspections help maintain battery health.

- Usage Patterns: Frequent deep discharges and heavy workloads can shorten lifespan.

- Environmental Conditions: Extreme temperatures and poor ventilation affect battery efficiency.

- Battery Quality: Higher-quality batteries and better manufacturing lead to longer-lasting performance.

Understanding these elements helps you make smart decisions for battery use, maintenance, and when to plan for replacement, ensuring your operations run smoothly and cost-effectively.

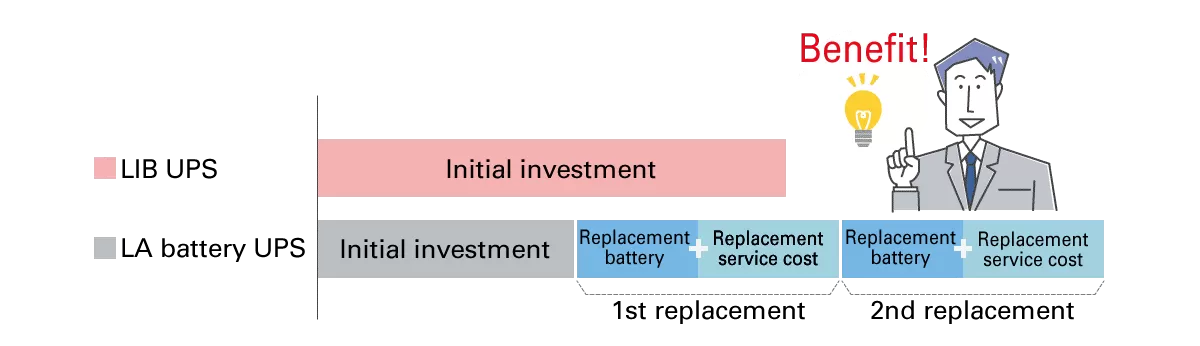

Lead-Acid vs Lithium-Ion A Lifespan Comparison

When comparing forklift battery lifespan, lead-acid and lithium-ion batteries are the two main options you’ll encounter. Each has its strengths depending on your operation’s needs.

Lead-Acid Batteries

Lead-acid batteries have been the industry standard for years. Typically, they last about 1,200 to 1,800 battery cycles, which translates to 3 to 5 years with proper lead-acid battery maintenance. These batteries require regular watering, cleaning, and scheduled equalizing charges to keep their performance steady. While they’re generally less expensive upfront, long charging times and downtime for maintenance can affect warehouse battery efficiency. Plus, they’re bulkier and heavier compared to lithium-ion.

Lithium-Ion Batteries LI-ESS Focus

Lithium-ion forklift batteries, like those from LI-ESS, are gaining ground fast. They last roughly 2,000 to 3,000 battery cycles, which can stretch the battery life to 6-8 years, sometimes longer. Lithium-ion batteries offer faster charging, opportunity charging benefits, and reduced maintenance since you don’t have to worry about watering or acid spills. The LI-ESS line, made with quality and reliability in mind, offers top-tier performance that fits well with modern electric forklift operations in the US market.

Which Is Right for Your Operation

If your warehouse runs multiple shifts and needs fast charging with minimal downtime, lithium-ion, especially LI-ESS batteries, can save you time and money over the long haul. But if your operation has a tighter budget and can manage regular maintenance, lead-acid batteries are still a reliable choice. Consider your use frequency, budget, and maintenance capabilities when deciding which forklift battery type fits your operation best.

Maximizing Forklift Battery Life Practical Tips

Getting the most out of your forklift battery means following a few simple but important steps. Whether you’re using a lead-acid battery or a lithium-ion forklift battery, proper care extends electric forklift battery life and saves you money in the long run.

Proper Charging Practices

- Charge at the right time: Avoid fully draining the battery before charging. Opportunity charging during breaks keeps the battery healthier.

- Use the correct charger: Match your battery’s voltage and type. For example, lead-acid needs a different charger than lithium-ion.

- Avoid overcharging: Overcharging can cause battery damage and reduce battery cycle life. Use chargers with automatic shut-off features.

定期維護

- 定期檢查: 檢查腐蝕、鬆動的電纜和損壞的連接器。

- 保持乾淨: 灰塵與碎屑可能影響電池接點與性能。

- 水鉛酸電池: 保持適當的水位並使用蒸餾水以避免損壞。鋰離子電池需要較少的維護,但仍需定期檢查。

環境考量

- 妥善存放: 將電池存放在陰涼乾燥的地方,遠離極端溫度。

- 避免嚴苛的條件: 過度的高溫或低溫可能會縮短堆高機電池的壽命。

- 通風是關鍵: 尤其對於鉛酸電池,充電時請確保良好的通風,以避免氣體積聚。

監控電池健康狀況

- 使用監控工具: 許多叉車電池都配備內建指示器或智慧監控系統。

- 追蹤充電循環次數: 了解您的電池循環次數有助於規劃更換並避免意外停機。

- 安排專業檢查: 如果性能下降或你注意到問題,請讓電池專業人員檢查。

遵循這些提示可以讓您的叉車電池保持最佳狀態,提升倉庫電池效率,並幫助您的作業順利進行。

為何選擇LI-ESS鋰離子叉車電池

如果你正在考慮升級你的叉車電池,LI-ESS 鋰離子電池是一個可靠的選擇。它們比傳統的鉛酸電池提供更長的叉車電池壽命和更佳的性能。以下是為何 LI-ESS 在台灣倉儲作業中脫穎而出的原因:

-

較長的電池循環壽命

LI-ESS 鋰離子電池可以承受更多的充電循環,無需更換。這意味著更少的電池更換次數,以及隨著時間推移較低的堆高機電池更換成本。

-

快速充電與機會充電

你可以在短暫休息期間快速充電這些電池,讓你的電動堆高機電池在長時間工作中保持活躍,無需停機。這將提升倉庫電池的效率。

-

低維護

與鉛酸電池不同,LI-ESS 鋰離子電池幾乎不需維護。無需加水或平衡充電,這簡化了叉車電池的維護並節省您的時間。

-

穩定的電力傳輸

LI-ESS電池在放電過程中保持穩定電壓,確保您的叉車平穩運行,沒有性能下降或減速。

-

更安全且環保

以品質與安全為設計理念,LI-ESS 電池組降低了舊型電池常見的火災或洩漏風險。此外,它們更環保,與日益提升的產業永續標準相符。

-

隨著時間的成本節省

儘管前期價格可能高於鉛酸電池選項,但較長的電池壽命、較少的維護需求以及更高的效率意味著較低的總持有成本。

選擇 LI-ESS 鋰離子堆高機電池意味著投資於可靠的電力,能很好地配合台灣倉庫和工業場所的快速節奏與需求。它們經過驗證的品質和對性能的專注,使其成為保持運作順暢的明智選擇。

常見問題

一台叉車電池可以使用多久?

平均叉車電池的使用壽命介於4到6年之間,但這取決於電池類型、使用情況和維護狀況。

影響叉車電池壽命最大的是什麼?

充電習慣、維護、運行環境和循環頻率等因素都會影響電池壽命。

哪一種壽命較長,鉛酸或鋰離子叉車電池?

鋰離子電池通常壽命較長,大約6到8年,而鉛酸電池在妥善保養下平均壽命為4到6年。

我應該多久為我的叉車電池充一次電?

定期充電並避免深度放電。對於鉛酸電池,每次使用後充滿電是最好的。鋰離子電池支持快充,因此較短且頻繁的充電效果良好。

維護我的叉車電池的最佳方法是什麼?

保持終端乾淨且緊密

定期檢查鉛酸電池中的電解液液位

請使用適合您的電池類型的充電器

將電池存放在陰涼乾燥的地方

我可以在現有的叉車中使用鋰離子電池嗎?

有些叉車可以改裝為鋰離子,但請與您的供應商或製造商確認相容性。

機會充電有益嗎?

是的,尤其是對於鋰離子電池。它有助於維持充電而不損害電池壽命,提升倉庫效率。

我應該何時考慮更換叉車電池?

如果您注意到運行時間急劇縮短、充電時間變長或出現物理損壞,可能是時候更換電池了。定期監測有助於及早發現這些跡象。